Are you planning a big project that requires waterproof epoxy? Whether it be an indoor or outdoor project, waterproof epoxy can help ensure your project remains secure and safe from water damage. But if you’re new to using this specialized material, the process of finding the right kind can be confusing.

That’s why we’ve created this comprehensive guide to waterproof epoxy in 2023 – so you can make sure your projects are successful without having to worry about any hidden risks!

Read on to learn more about what makes different types of waterproof epoxies unique, tips for making sure they meet safety standards and suggestions for where you can purchase quality products.

Table of Contents

- 1 What is waterproof epoxy?

- 2 Benefits of using waterproof epoxy resin

- 3 What makes the best waterproof epoxy resin?

- 4 Using epoxy sealant for waterproofing

- 5 Painting with epoxy coating and waterproofing your swimming pool

- 6 A high-level summary of waterproof epoxy

- 7 Frequently Asked Questions About Waterproof Epoxy

What is waterproof epoxy?

Waterproof epoxy is a versatile material composed of two separate parts: a resin and a hardener. When mixed, they form epoxy that, unlike other resins and glues, is waterproof.

This makes it ideal for underwater applications such as boatbuilding, aquariums, plumbing repairs, marine installations, and more. Its use has become increasingly popular with aerospace engineers looking for materials to use in external components or areas exposed to water, as well as in the automotive and electronics industries where water resistance is highly valued.

The first epoxy resin was invented in 1936 by Dr. Pierre Castan of France who used it as an alternative to animal-based glues such as hide glue and blood albumin. It has since become essential in many areas due to its versatility and reliable protection from water damage.

Is all epoxy resin waterproof?

Epoxy resin is not always considered waterproof, though it can be used as a waterproofing material in some contexts. However, the term ‘waterproof’ generally refers to a completely impermeable surface that does not allow moisture to penetrate or pass through, while epoxy resin may still permit water vapor or droplets to pass through the material.

For example, an epoxy coating applied to concrete could protect against occasional wetting but would be unable to protect against full immersion in water. When compared to other common waterproofing materials such as coatings, sealants and membranes, which are more able to withstand extended exposure to water and humidity, epoxy resin does not have quite the same level of performance. Despite this limitation, for certain kinds of applications, epoxy resin can provide an effective yet affordable solution for waterproofing. There are also many epoxies on the market that are specifically formulated to be waterproof – this paragraph is just to note that not all epoxies are completely waterproof.

Benefits of using waterproof epoxy resin

There are quite a few different benefits when using a waterproof epoxy resin.

Durability

Waterproof epoxy resin is extremely durable and can often last multiple decades without needing to be replaced.

Resistance to chemicals and impact

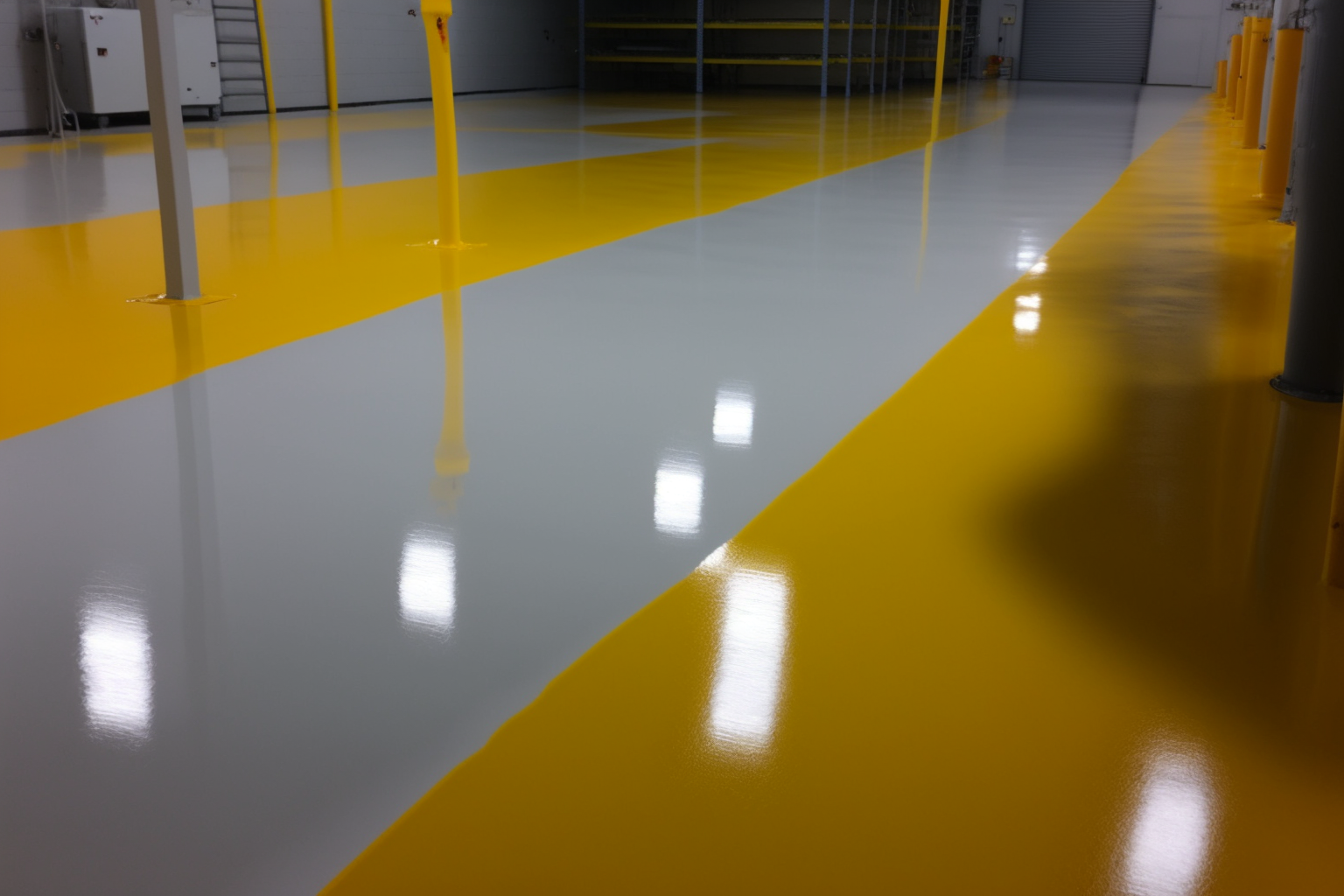

Waterproof epoxy resin is highly resistant to chemical exposure and damage from impacts. This makes it a great choice for areas that are exposed to corrosive chemicals or mechanical stress, such as industrial settings.

UV resistance

Epoxy resins usually have excellent UV resistance, making them suitable for outdoor use in direct sunlight where other materials may not

Cost-effectiveness

The cost of waterproof epoxy resin is usually much lower than other waterproofing materials, making it a great choice for those on a budget.

Ease of application

Waterproof epoxy resin is also relatively easy to apply, making it a good choice for both professional and DIY projects.

What makes the best waterproof epoxy resin?

When choosing the best waterproof epoxy resin, the quality of materials is a key factor. Look for resins containing advanced compounds designed to provide superior adhesion and flexibility.

Another important consideration is compatibility with different surfaces. Many products on the market are not suitable for use with specific materials such as aluminum or cast iron, so it is essential to make sure your chosen product will suit the material you are applying it to before you buy it.

Finally, read reviews and be sure to check that the product meets industry standards for waterproofing solutions before making your selection.

Using epoxy sealant for waterproofing

Using epoxy sealant is an effective way of waterproofing surfaces. Once it dries, it forms a strong bond creating an impenetrable seal that protects surfaces from water damage.

To ensure the successful application of epoxy sealant, make sure that the surface you’re waterproofing is dry and clean before application, use caution around fabrics, furniture, or carpets as the mixture may leave a stained residue, and follow instructions carefully in order to achieve the best possible coverage results over time.

Application variables to consider

When using waterproof epoxy, it’s important to consider application variables such as surface preparation, temperature and humidity conditions, time and curing process and health and safety precautions. All of these factors play an important role in achieving optimal results from your project.

Proper surface preparation ensures that the background is optimally clean so that the adhesive properly bonds with your materials.

Temperature and humidity conditions can also affect how quickly the epoxy cures, so be sure to use a hygrometer if necessary to ensure that you have favorable environmental conditions.

Taking into account the required time for curing allows you to properly plan out the length of time needed for completing a project.

It’s also essential to take health and safety precautions when working with waterproof epoxy, including proper ventilation during application as well as wearing protective clothing while handling the product.

Painting with epoxy coating and waterproofing your swimming pool

Painting your swimming pool with an epoxy coating is a great way to add a new look while reinforcing its durability.

To do this, you’ll need to prepare the surface of the pool first by cleaning and etching it (assuming it is made of concrete or similar material). You should then prime it with an epoxy patch material before applying the epoxy paint, using smooth brush strokes in even layers across all surfaces.

Keep in mind that direct sunlight and constant exposure to water can cause problems like fading, chalking, and peeling so be sure to use high-quality, specialized paints that are designed for environments like swimming pools, as well as protective top coats to preserve color and longevity of the paint job.

A high-level summary of waterproof epoxy

Waterproof epoxy is an effective solution for waterproofing surfaces and protection against water damage. It consists of two parts – a resin and hardener which are mixed together to form a strong bond that creates an impenetrable seal.

Application variables such as surface preparation, temperature, and humidity conditions, time and curing process, as well as health and safety precautions, should be factored into your project for optimal results. Epoxy coatings are also ideal for painting swimming pools and other water-exposed surfaces, as their strong bond helps to preserve the quality of the paint job.

In short, waterproof epoxy is a cost-effective and reliable solution for many waterproofing needs.

Frequently Asked Questions About Waterproof Epoxy

Can the shower floor be epoxy painted?

Yes, epoxy paint can be used on shower floors. Make sure to properly prepare the surface by cleaning and etching it before applying the primer and paint. Also, use specialized paints designed for wet environments to prevent fading, chalking, or peeling.

Can you use epoxy resin outdoors?

Yes, epoxy resin can be used outdoors as long as it is applied properly. Make sure to use a primer before applying the epoxy and avoid direct sunlight or constant water exposure. Additionally, choose specialized paints designed for outdoor use and apply protective top coats for added protection against the elements.

Can you waterproof wood with epoxy?

Yes, epoxy is an effective solution for waterproofing wood. Before applying the epoxy, make sure to properly clean and etch the surface so that it can accept the adhesive. Also, consider environmental conditions such as temperature and humidity when working with epoxy as these can affect how quickly it cures. Take into account the required curing time before proceeding.